Home Facilities

Our cut and fold department is equipped with state-of-the-art machinery, including a Bystronic Fibre Laser 4020 8kW with a 4m x 2m bed and Bytrans loading system.

It also includes SAF OCP150 Plasma, SAF CPM400 Plasma, and Esprit Viper PR 300 plasma machines, complemented by multiple press brakes, including a 400T Durma tandem press brake with a 7m fold length.

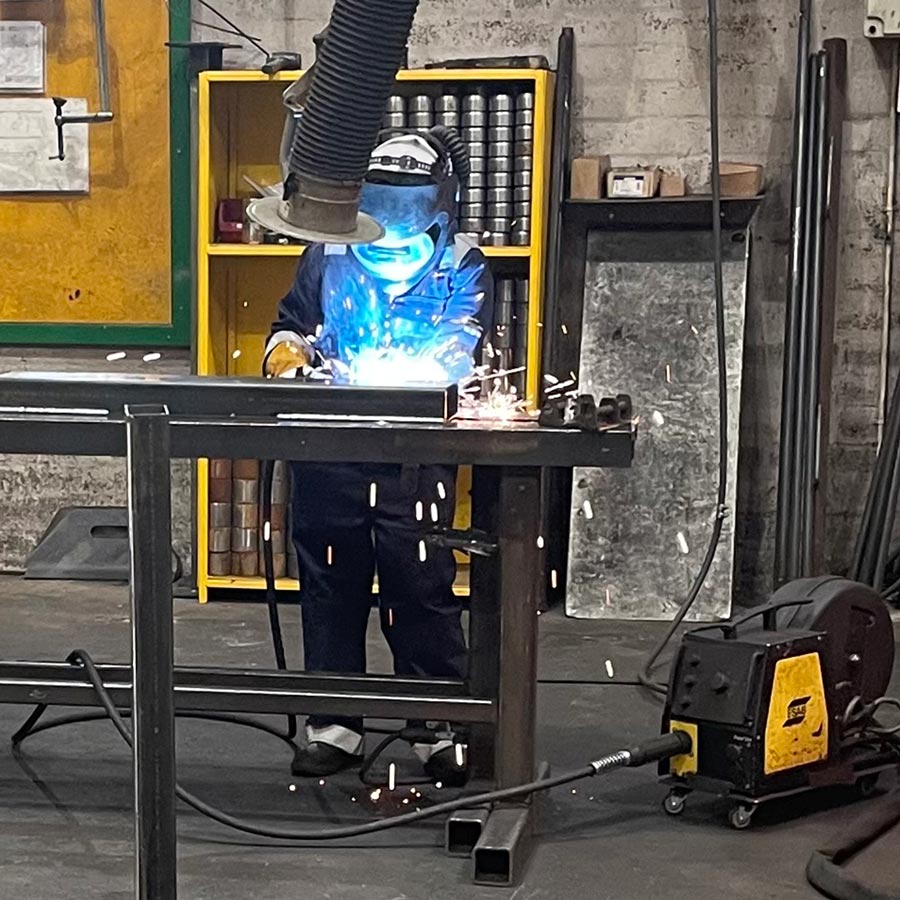

Our dedicated welding bays are equipped with a full Local Exhaust Ventilation (LEV) extraction system, meeting Health and Safety Executive (HSE) standards, alongside 10-tonne and 5-tonne gantry cranes for efficient fabrication movement.

Additionally, we provide paint booths and a dedicated shot blasting shed, featuring two fully operational paint shops.

Our fabrication assembly area boasts a skilled fitting team and is fully equipped with 5 and 10 tonne cranes for seamless operations.

Our dedicated quality team conducts electronic pre-dispatch inspections, while a customer account manager offers regular delivery updates and handles any inquiries.

Additionally, we utilise two articulated lorries for deliveries and have container loading facilities to support international shipments.

By requesting a callback from Specdrum you are agreeing that we can contact you in accordance with our Privacy Policy.

By requesting a callback from Specdrum you are agreeing that we can contact you in accordance with our Privacy Policy.